It's simple to assume that Sourcing and Procurement are interchangeable terms for acquiring supplies for an organization based on their apparent meanings. They aren't. Although they are related and both have important roles in your organization's supply chain, they are quite different and must be used in different ways to guarantee your company's success.

In this article, we will take you through what sourcing and procurement are, why they're important, the steps involved in each of these supply chain components and what can be done to improve their efficiency.

Let's begin with Procurement.

Procurement is an element that contains Sourcing. The procurement process impacts the entire supply chain. Although several companies have realized its significance, it still needs to earn recognition like the other elements of a reputed supply chain.

Your supply chain's main source of revenue is Procurement. It will be essential for a supply chain to purchase the necessary materials before it can start producing manufactured goods.

So, the question which arises is:

The simplest definition of Procurement is the process of conducting transactions with vendors, getting confirmation of the orders, paying for them, and then checking to make sure everything was delivered as promised. A company might waste significant resources without a solid approach to getting the supplies it needs to run, which shows that Procurement is the foundation of a supply chain.

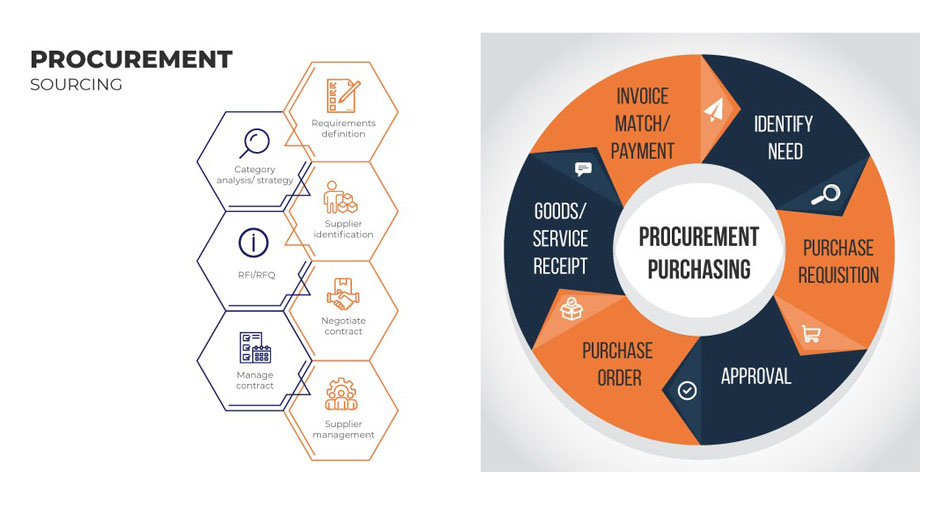

To better grasp the subject, let's examine the entire procedure:

Process:

This process entails numerous steps. The materials you need could be obtained with a quick email or phone, but this isn't as simple as several variables are involved. Have a look at the summary of the entire procedure:

• Identify Your Needs - What supplies are required for success?

• Make a purchase request- List the necessary materials in an official purchase request.

• Obtain a review of your purchase request - Permit administration to conduct it.

• Contracts should be negotiated- Talk about the terms of the contracts.

• Request quotes -Learn about expenses and ascertain whether they fall within your price bracket.

• Obtain Budget Approval – Supplies will be delivered as soon as the relevant parties have consented.

• Accepting Goods - Acquiring, arranging, and storing the requested materials

• Check Invoice Against Purchase Order And Receiving Report - Verify no discrepancies or incomplete items are using a process called three-way matching.

• Invoice Payment- Reimburse the vendor for your products after receiving an invoice.

• Keep Transaction Records - Keep thorough, organized records to hasten future follow-up shipments.

This isn't a straightforward task. Organizing, working together, and exchanging information rapidly are essential components of a sturdy cycle. Using a system is one of the best ways to maintain order. Numerous features included in these platforms simplify this process and make it less complicated.

In order to remain competitive, more and more businesses will adopt cutting-edge technology as the business technology landscape continues to evolve toward digitalization.

Surprisingly, a recent study reveals that only one in four supply chain professionals have a digital approach in place, even though 94% believe digitization will change how supply chains are structured.

Keep a couple of essential tools in mind when looking for your software solutions:

• Interactive Dashboards:

A crucial component that aids in turning information into comprehensible visuals is the dashboard. Your significant request status updates and other urgent information will appear here. They don't need to be adaptable, but it doesn't endanger having the option to give your dashboard a personalized look to best fit your frameworks.

• Easy Integrations:

It's crucial to have compatibility with the technology you use most frequently. Seek clarification from suppliers if their portals support integration with any of your favored apps and API.

• Real-Time Reports and Data Visibility:

Planning and managing demand depend on having visibility tools readily available. Many systems have tools that produce real-time reports on the crucial tasks you perform each day so you can figure out which ones are struggling. Furthermore, these tools enable users to plan for the future while preventing issues from arising.

Below are some factors to think about:

• Risk Mitigation Tools

• Pre-Generated Templates

• Customizable Features

• Cloud-Based Storage

• Spend Control Support

This was all about Procurement. Now let's pay attention to clarify our understanding of Sourcing.

Now, let's discuss Procurement's twin, 'Sourcing.' Though Procurement is the main step that results in business success, Sourcing is what makes Procurement possible. It is an integral aspect of Procurement. Locating and evaluating suppliers is essential before your valuable materials can be ordered and shipped to your manufacturing locations.

To precisely define, Sourcing entails locating, verifying, and obtaining the required materials from the listed suppliers.

Even though the procurement process is much prolonged, Sourcing is just as significant and makes everything else possible:

• Develop your Consumer's Needs

It is essential to fulfilling customers' demand for the product, and as a sourcing supervisor, you must ensure that you obtain all the required materials for production. This procedure can be divided into a few simple steps:

• Determine Customer's Needs

• Construct Material Specifications

• Assess Market Offerings

• Characterize Successful Supplier Characteristics

• Assess the Market:

The next step is giving suppliers a chance to submit a quote and examine how a partnership with them would pan out. An RFI or RFQ is typically used to start this process:

• Request for Information (RFI):

• Assists in vetting suppliers before an RFQ is issued

• A quick survey to help focus the suppliers' market

• Sending one out is optional; you are not obligated to do so.

• Request for Quote (RFQ)

• Officially inquiring about a supplier for a price quote

• An RFI is much simpler than this, typically including detailed project data and bid details.

• Negotiation:

You have now invited a few vendors and selected your choices among them. Then you'll begin with the bargaining process. You now initiate the meeting with suppliers to learn what they can provide to enhance the appeal of their services. The moment has arrived to demand lower costs, more preferable payment terms, and similar things.

By completing this process, you ought to have a supplier who satisfies your needs.

What are the Differences Between Procurement and Sourcing?

Now that we have learned what exactly is Sourcing and Procurement, we'll further discuss the difference between Sourcing and Procurement.

Purchasing products for your business or store is known as Procurement, whereas Sourcing refers to discovering where to buy high-quality, budget-friendly products.

1. Procurement can occur without Sourcing.

For instance, A company with a larger budget might occasionally instruct the procurement manager to purchase 30 computers from the nearby computer store because it's probably the only one close to their office. The procurement manager can design the process, including price negotiations and eventual computer purchase. But this doesn't mean that Sourcing holds no value. It has its worth.

2. The entire procurement process is simplified by Sourcing

A unit of credible sourcing experts is a privilege for the procurement manager. The sourcing specialist will provide the procurement manager with a list of the top places where they can purchase the stuff the firm requires. And through that list, procurement managers can plan things accordingly, thus saving their time and effort.

3. Sourcing aims to determine who is producing the supplies, while Procurement concentrates on the what of the supplies.

The quality and cost of the office supply items are crucial factors for the procurement manager. With those, they can decide if the supplies are suitable for purchase. In the meantime, Sourcing focuses on the source of the materials or supplies. This is to ensure that the source is trustable and modestly priced.

4. Sourcing ensures that the distribution system that generates the inputs and supplies is secured, whereas Procurement focuses on the smooth flow of inputs and supplies.

Procurement and Sourcing can only operate in groups. They collaborate to ensure that the materials required for the business to continue operating are delivered without issues. Relating it to an example, people assume sourcing is the oil that keeps the cogs running smoothly, and Procurement is the machine's internal parts that make it function.

Below is an illustration of the distinction between Procurement and Sourcing.

Why There Seems to be a Necessity to Know the Difference Between these Two Terms?

We have closely looked at Sourcing vs. Procurement: the difference. But we also need to focus on the 'why' aspect. Below are a few reasons which will further provide us with clarification on this subject.

• Procurement managers still have the misconception that both Procurement and Sourcing are the same; thus, they fail to take into account the significance of Sourcing in the procurement process.

• You'll save time and money by realizing the benefits of sourcing for your business. Before you begin the procurement process, you can create a sourcing process to look for potential suppliers.

• A procurement manager incapable of distinguishing Sourcing and Procurement will not be able to fully utilize the automated program when automated procurement systems are required.

• Procurement managers should be familiar with the distinction between Sourcing and Procurement to make the firm competitive.

• The procurement managers will always benefit if they have the basic knowledge of Procurement and Sourcing as they'll have the edge in negotiating with the vendors. You can choose from the best suppliers and bargain for lower costs per supply.

Utilizing Sourcing in the procurement process is important, but Sourcing should be planned and consider the overall business rather than the individual elements to make it efficient. Therefore, businesses incorporate 'Strategic Sourcing' to analyze things perfectly.

Strategic Sourcing is identifying, evaluating, and selecting suppliers who can provide goods and services that meet a company's needs while achieving the best value for money. It involves developing long-term relationships with suppliers who can provide reliable, high-quality goods and services at competitive prices.

The strategic sourcing process typically involves several steps, including identifying the company's needs, analyzing the market to identify potential suppliers, evaluating potential suppliers based on criteria such as quality, cost, delivery times, and reliability, negotiating with suppliers to secure favorable terms, and monitoring supplier performance over time.

Strategic Sourcing aims to create a sustainable competitive advantage by improving the company's overall supply chain efficiency and effectiveness.

By developing long-term relationships with suppliers, companies can reduce costs, improve the quality of the goods and services they receive, and minimize the risk of supply chain disruptions.

Strategic Sourcing is a key component of supply chain management, and it requires collaboration and communication across different departments within a company and with external suppliers.

It can be a difficult and time-taking method. Still, the benefits of a well-executed strategic sourcing strategy can be significant, including improved financial performance, increased customer satisfaction, and a stronger competitive position in the marketplace.

There are several benefits of adopting Strategic Sourcing:

• Better quality raw-materials

• Increased supply chain sustainability

• Strong supply chain risk management

• Long-term cost savings

• Increased negotiating power

• Better understanding of the market.

Incorporating such strategies in businesses will eventually lead to business success.

Any organization needs Sourcing and Procurement to ensure the products and services it needs to operate are acquired at the best possible price and quality. Costs can be decreased, efficiency can be increased, and the supply chain's overall performance can be enhanced using effective sourcing and procurement techniques.

However, these tasks are challenging, and businesses must be equipped to handle problems like supplier relations, supply chain disruptions, and shifting market dynamics. Organizations can improve the efficiency of their supply chains and gain a competitive edge in the market by adopting a strategic sourcing and procurement approach.

Perhaps, there is always an option for business to achieve the efficiency by looking for high-quality software solutions that can help streamline their procurement process and help in the growth of company through competitive supply chains.